F-128: Expansion of the Apple Harvest Season

Expansion of the apple harvest season is most effectively obtained with selection of cultivars and strains that provide suitable quantities of fruit of the highest quality distributed throughout the harvest period. However, consumer and market demands and the physiology of the apple tree often prevent growers from attaining this goal. Three particular problems arise: the need to have fruit of a particular cultivar available for the farm stand and pick-your-own customers before and/or after the normal harvest date; the need to have more fruit of a particular cultivar available for the marketplace than can be harvested in the optimal time period; and the need to control premature, natural dropping of fruit from the trees. Previous factsheets have discussed the use of summer pruning as an approach to advance the harvest season to some degree, but substantial advancement or delay of the harvest season and control of premature drop of specific cultivars can occur only through the use of plant-growth- regulating chemicals. In this fact sheet, approaches will be divided into those which reduce or delay fruit drop and those which advance ripening a color development.

Reduction or Delay of Fruit Drop

Two chemicals are available to control apple fruit drop: naphthalene acetic acid (NAA) and aminoethoxyvinylglycine (AVG). Neither is ideal; however, each can be used to delay drop, and AVG can be used to delay harvest for 7 to 10 days.

NAA

NAA is in the naturally occurring class of hormones called auxins. It has two effects on apple fruit. First, it interferes with the action of ethylene, the gaseous hormone which initiates ripening and many other processes related to plant senescence. Blocking ethylene action at the abscission zone (where the fruit’s stem is attached to the tree) delays drop. Secondly, NAA enhances ethylene synthesis. This effect, unfortunately, enhances fruit ripening (the amount depending on concentration and number of applications, weather following application, and time between application and harvest), resulting in reduced storage potential and making NAA less than an ideal chemical treatment. Additionally, individual applications are only effective for 7 to 10 days, it must be applied at a time when it is not desirable to run spray equipment in the orchard, and weather may prevent timely reapplication.

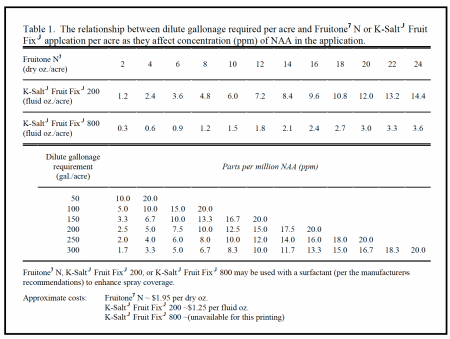

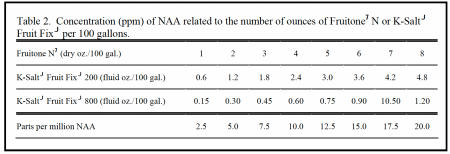

Application. The traditional timing of the first NAA application was when drop of a significant number of many-seeded, blemish-free fruit had commenced. The drop-controlling effects of NAA take 1 to 3 days to begin, so often when using this approach, too many fruit were lost before the rate of drop was reduced. To prevent this problem from occurring, NAA should be applied 7 to 14 days prior to normal harvest in blocks where drop control is desired. (See Tables 1 and 2 for the relationships among formulated product, ppm NAA, and dilute gallonage required per acre.) Once the foliage has dried after application, rain should not decrease the effectiveness of NAA. Early-season cultivars can be treated with a 10 ppm NAA solution, and a delay in drop of 7 days can be obtained. Longer control can be obtained by the use of a repeat application after 7 days. Mid- and late-season cultivars can be treated with 10 to 20 ppm NAA, giving 7 to 10 days of drop control. Longer control can be obtained with an additional application after 7 to 10 days. With late-season cultivars, applications should be made before frost injures the leaves. A normal surfactant may be used with NAA to enhance spray coverage. In general, NAA should not be used to delay harvest beyond the normal date.

Three formulations of NAA are commercially available for the reduction of apple drop: Fruitone® N, K-Salt™ Fruit Fix™ 200, and K-Salt™ Fruit Fix™ 800. The restricted-entry interval (REI) for Fruitone® N is 48 hours, and the preharvest interval (PHI) is 2 days. The REI for K-Salt™ Fruit Fix™ (200 or 800) is 24 hours, and the PHI is 2 days.

AVG

AVG is a plant growth regulator that works by inhibiting the production of ethylene in the plant tissues. It was discovered in the 1970s, and we worked with it extensively in the late 1970s and early 1980s, but our focus was on fruit set and fruit ripening. It was impressive to see how well it retarded apple ripening. After the registration for Alar® was cancelled, work with AVG began again, this time focusing on its ability to retard fruit drop. ReTain®, the commercially available formulation of AVG, can very effectively delay the development of drop by 7 to 10 days or more, thus allowing an expansion of the harvest season. At the concentrations possible with the commercial formulation, other effects include a small but measurable delay in ripening. The delay in ripening includes slightly firmer fruit, reduced red color development, lower soluble solids concentration, and less watercore. If treated and non-treated fruit, however, are harvested at the same degree of ripeness, there is little difference in fruit quality, except that treated fruit may be greener. The primary problem with the use of ReTain® is cost, more than $250 per acre. This constraint should focus its use on blocks and cultivars where a delay in ripening and/or drop is most needed. Growers will not be able to afford application to whole farms.

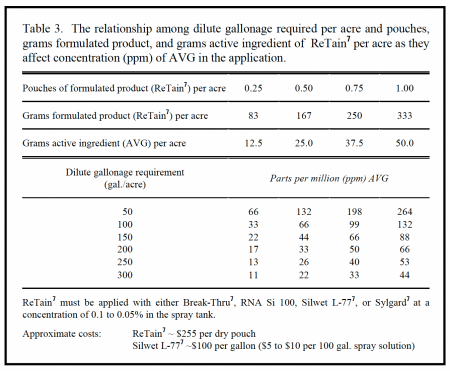

Application. ReTain® may be applied at a rate of up to one pouch (333 grams) per acre. The response to AVG, however, is concentration dependent. If one pouch is applied to an acre of trees that requires 50 gallons in a dilute application, the effective concentration of AVG is 264 ppm. On the other hand, if one pouch is applied to an acre of trees requiring 300 gallons in a dilute application, the effective concentration of AVG is only 44 ppm, In this example, you would expect 1/6 of the response from AVG on the trees requiring 300 gallons dilute, compared to those requiring only 50 gallons. The relationship among dilute gallonage application rate, and AVG concentration are detailed in Table 3. To obtain the most economically viable response, you must apply a dilute concentration equivalent of at least 50 ppm.

Time the AVG application about 4 weeks before the beginning of the normal harvest period (that is, if AVG was not applied). Its effect dissipates if applied too early, and it may miss some of the early-ripening fruit on the tree if applied too late. Try to select a period when rain is not expected within 24 hours of the application, since AVG is very water soluble, and rain events within 24 hours have been shown to reduce effectiveness. Also, do not apply AVG within 4 days of a calcium chloride application; the surfactant likely will enhance uptake of the calcium chloride to the point of phytotoxicity.

ReTain® must be applied with one of the following surfactants: Break-Thru®, RNA Si 100, Silwet L-77®, or Sylgard®. Please note that Silwet L-77® and Sylgard® are the only ones readily available on the East Coast. Concentration should be 0.05 to 0.1 % of the spray solution, and if ReTain® is applied at 2X or a higher concentration, do not concentrate the surfactant. Good coverage is necessary, so AVG should be applied in as dilute a spray as possible. Most research with AVG has been conducted with McIntosh and Delicious; however, some studies have been done with other cultivars, and there is no reason to expect that it would not have some effect on any apple cultivar. Research with Gala suggested, however, that its response to AVG is excessive. Reduced rates on Gala would be most desirable.

The REI for ReTain® is 12 hours, and the PHI is 21 days.

Advancing Ripening and Color Development

Ethephon may be used to advance ripening and enhance red color development of apples, thus providing a means of advancing the harvest season. However, ethephon must be used with caution. Ethephon can add 10 to 30% red color to fruit borne on the periphery of the tree, but conditions which naturally discourage coloring may prevent ethephon-treated fruit from obtaining adequate color development. Summer pruning will improve light penetration and make a tree more suitable for ethephon treatment.

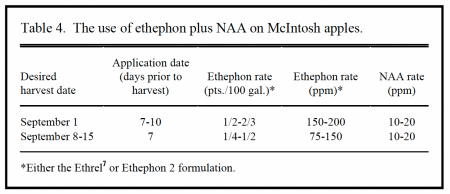

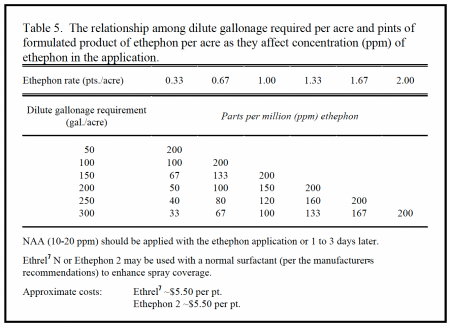

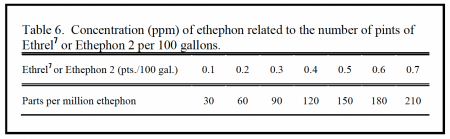

Application. Table 4 lists the recommend rates and timings of ethephon application to McIntosh (also see Tables 5 and 6). NAA should be included to prevent premature drop (see Tables 1 and 2 for more specific information on NAA concentration as it relates to dilute gallonage required per acre and the rate of formulated product). The stop-drop effects of NAA will last for 7 to 10 days, so if fruit are to be left on the tree more than 10 days after ethephon treatment, a second application of NAA will be necessary. Alternatively, ethephon may be applied alone, with NAA applied 1 to 3 days later. Fruit from trees treated with low rates of ethephon (e.g., 75 ppm) with a reduced amount of NAA (10 ppm) can be kept in short-term cold storage. A normal surfactant may be used with ethephon to enhance spray coverage. We recommend that any new users treat small areas and pay careful attention to fruit color and maturity. Fruit should be examined daily or twice daily from about 5 days after treatment until they reach the desired percent color. However, be prepared to harvest ripe fruit, even if they do not reach adequate color. In areas where normal color development is good, reduce the ethephon concentration. In general, experiment in your orchard and use as little ethephon as possible to obtain the desired results.

The REIs for both Ethrel® and Ethephon 2 are 48 hours, and the PHIs for both are 7 days.

UMass Extension Fact Sheet F-128

Issued by University of Massachusetts Extension, Stephen J. Demski, Director, in furtherance of the acts of May 8 and June 30, 1914. University of Massachusetts Extension offers equal opportunity in programs and employment. F-128:4/02-500