Selecting and Maintaining Thermostats

How would you like to make $100-$200 for a simple 15 minute maintenance procedure in your greenhouse. This is the potential fuel savings from improving the accuracy of a heating thermostat. There are not many tasks that will give this large a return.

The above savings is based on a 30' x 100' double covered greenhouse where the average winter temperature is 25ºF. and the fuel costs are $15/million Btu (equivalent to fuel oil at $1.50/gal., natural gas at $1.05/therm and propane at $0.88/gallon). It is also based on a desired night temperature of 60ºF and thermostat setpoint that is 1-2 degrees too high.

Thermostats tend to loose accuracy over time

All thermostats should be checked for accuracy at least once a year. Start by checking the accuracy of a good thermometer by inserting it in an ice water bath. The reading should be 32ºF.

After allowing the thermometer to reach room temperature, place it next to the thermostat sensor. The sensor should not be in direct sunlight. Slowly move the dial until the heater turns on. The reading should be the same temperature as the thermometer reading. If not, determine the temperature difference and mark the thermostat accordingly. Next time the heating system is serviced, have the service person recalibrate it.

Also while checking accuracy, clean the dust off the sensor coil and any interior exposed connections. If there are exposed contacts, use a contact cleaner or draw a piece of paper or a business card through them to remove corrosion. Check that all wire connections are tight and not broken.

Install the thermostat to sense plant temperature

Proper installation can also have an effect on thermostat operation. The thermostat must feel the air that the plants feel if you want to control the temperature in the plant zone. A good location is at plant height near the center of the growing area. Some growers install the thermostat so that it can be raised or lowered for different crops. A thermostat mounted on an endwall or sidewall of the greenhouse, a location that heating equipment installers usually choose will not give good results. Also be sure that it is not located directly above heat pipes or in the direct line of a duct outlet. Shade the thermostat so that it out of direct sunlight.

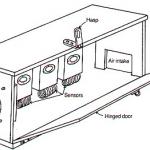

Locating the heating and cooling system thermostats in one location is desirable. Placing them inside a closed aspirated box that is painted white will give more accurate sensing. The box has a small muffin fan that draws air past the sensors. Tests at Rutgers University showed that the temperature spread (difference between high and low) in the greenhouse was reduced from 8ºF to 2ºF when the heating thermostat was aspirated. Energy is wasted any time the greenhouse air temperature is heated above the setpoint

Select a thermostat for the harsh greenhouse environment

There are many types of thermostats to choose from. When selecting one, look for moisture and dust tight boxes. Typical home thermostats have an exposed bi-metalic strip sensing element that can give erroneous signals when covered with dust or moisture. A better choice is a thermostat that has a sensor activated by pressure from the expansion of a liquid or gas in a coil of closed tubing.

The movement of the switch between the on signal and the off signal is called differential. This can vary between 4ºF to 6ºF for mechanical thermostats. If you want to maintain a minimum of 60ºF (setpoint) in the greenhouse, and you have a thermostat with a 5ºF differential, the furnace will start when the temperature falls to 60ºF but doesn't shut off until it reaches 65ºF. This override increases both heat loss from the greenhouse and heating cost. It is important to select a thermostat with a small differential. Some thermostats have a heat anticipator that shuts the heater off just before it reaches the shut off point. This will save some fuel.

Electronic thermostats can save considerable fuel dollars

Electronic thermostats have a smaller differential, usually +/- 1ºF. They provide more accurate control than mechanical types. The sensor is a thermistor and electronic control circuit. The smaller differential means that the furnace will shut off only a degrees above the setpoint. This reduces fuel consumption. Electronic thermostats typically have other built-in features including remote sensing, digital display of temperature, day/night setback and variable voltage output. The remote sensing allows the sensor to be placed up to several hundred feet away.

One disadvantage to the electronic thermostat is that the heating equipment cycles more frequently. With today's modern heaters and furnaces, the time that it takes the unit to reach peak efficiency is only a minute or two so rapid cycling doesn't affect efficiency much. Motors will be turned on more frequently which could cause more wear on the starter.

The savings in energy with an electronic thermostat results from less heat loss from the greenhouse surface as the heater shuts off only a couple of degrees above setpoint. If we assume the same 30' x 100' greenhouse from the above example, and compare a mechanical thermostat with a 6ºF differential to an electronic thermostat with a 2ºF differential, the lower average temperature created by the electronic thermostat will save about 500 gallons of fuel oil, 750 gallons of propane or 700 therms of natural gas over the heating season. This is significant and at the price of fuel today will give a short payback.

A little effort before the heating season starts can result in reduced heating costs this winter. This can make more dollars available for improvements to the greenhouse environment control system, such as a controller or computer that integrates all of the heating and cooling equipment.

John W. Bartok, Jr.Agricultural Engineer

Natural Resources Mgt. & Engr. Dept.

University of Connecticut , Storrs CT

May 2005

Resource

Bartok J. 2013. Replace your thermostats with electronic controller.