Small Scale Dairy Calf and Cattle Housing

Introduction

Several different designs for housing and handling facilities are suitable for small scale dairy operations taking into consideration the weather, topography, and the availability of feed and pasture. It is important to know all the rules and regulations with respect to location, design, and type of operation. Check with your local Building Inspector to obtain the required permits prior to building or renovating your existing facility. You should also talk to an experienced builder or contractor to ensure the cost of the facility is within the objectives of the operation

It is important to choose a location for buildings and handling facilities that is on well-drained soil with properly designed surface water drainage situated away from streams, other bodies of water and is not close to population centers. The barn should be served by a good all-weather driveway, or border on a high, well-drained service yard. Check with your county Natural Resources and Conservation Service (NRCS) office for recommended guidelines.

Figure1. A calf hutch with wire

fencing placed around for

more available room.

Calf Housing

Hutches - Calves can be raised in individual hutches that afford them the opportunity to move around, be fed individually, and allow for good ventilation and ease of cleaning. The key is to have the hutches placed about 2 feet apart to avoid contact (spread of disease). They should be positioned facing south, and placed on a well-draining material, such as a layer of sand, gravel, or stone for proper drainage. The hutches should also be well bedded. Straw and/or shavings as a top layer make a dry and comfortable bed. Fencing can be placed around the hutch (Figure 1.) to give the calf the opportunity to exercise. Hutches may also be placed in greenhouses or barns during harsh winter weather, but it is not always necessary since the hutch affords them warmth. At weaning, or about 8 weeks of age, calves outgrow hutches and need to be moved to alternative housing.

Figure 2. Individual calf pens

in a greenhouse facility.

Another option, which may be more cost effective, is to have the calves in individual pens under a greenhouse structure (Figure 2). If housed in groups, calves should have 30 square feet per animal. Avoid housing systems that place calves on cold concrete, rubber mats or slatted floors.

Weaning to 6 months of Age

Transitional housing for weaned calves up to 6 months of age can be a shed with pasture, or group housing in a hoop shelter or shed. Heifers in group housing need at least 35 square feet per animal.

Figure 3. Group housing with headlocks.

Over 6 months to Bred Heifers:

Most producers use loose housing to minimize work. It is best to separate the large heifers from the small. If you are able, leave liberal amounts of feeding space so that smaller animals will not be crowded out. Heifers 6 to 24 months old should each have 35-40 square feet.

As heifers grow, there are considerable changes in their needs for resting area and feeding space. Facilities for older heifers should be designed to meet an animal's requirements and labor ease. The housing structure for older heifers should allow for convenience of:

- Feeding

- Cleaning and bedding

- Moving and restraining animals

Figure 4. A hoop barn is one of the least expensive

structures for housing.

Hoop barns – One of the least expensive structures for housing cattle is the hoop barn (Figure 4). Disadvantages are heat and ventilation problems during the summer months, but this should not be an issue if you are planning on grazing your cattle during the warmer months.

Figure 5. Open sided, single slope roof shed is one

of the most common housing structures.

Open sided, single slope roof shed - This type of housing is the most typical kind of structure used and is suitable for all cattle on the farm (Figure 5). They are the least expensive of new structures and very easy to build. Open sheds should face the south for winter sun and block the prevailing winds. Pole barns of this design can be partitioned for groups of animals without complicated interior construction. The installations of headgates are recommended when working with loose housing operations. Headgates come in four basic types; self-catching, scissors-stanchion, positive-control and fully opening stanchion. The self-catching headgate closes automatically due to the movement of the animal. The scissors-stanchion type has bi-parting halves that pivot at the bottom. The positive-control type locks firmly around the animal’s neck. The fully opening stanchion consists of two bi-parting halves that work like a pair of sliding doors. The self-catching, scissor-stanchion and the fully opening stanchion are available with either straight or curved stanchion bars. The straight-bar stanchion is extremely safe and will rarely choke an animal. The disadvantage of a straightbar is that animals cannot move their heads up and

down unless a nose bar is used. The curved-bar stanchion offers more control of the animal’s head but is more likely to choke the animal than the straight-bar type. Both types are safer than the positive-control headgate. No matter which type of headgate is selected, proper adjustment for the type of cattle being worked is necessary to prevent injury to the animals.

Milking Herd

Milking cattle may be housed in tie stalls, freestalls, or bedded-pack barns.

Cows typically rest 9 to 14 hours per day in intervals of five or more hours. Cows should be turned outside, for a minimum of one hour, at least once per day, for exercise (weather permitting), during the non-grazing

season or when appropriate conditions for grazing do not exist. This is especially important for cows in tie stall barns.

Figure 6. Tie stall housing allows for individual

cow monitoring especially for animal health.

Tie stall housing allows the farmer greater interaction with the herd. This type of system is good for small herds with fewer than 100 cattle. Good ventilation is critical in this type of housing. Table 1 shows the recommended dimensions for tie stalls

based on cow size. The stall should be large enough to allow the largest cow in the herd to freely enter the stall, lie down, rest comfortably and easily get to her feet and exit the stall.

| Cow Size | Platform width | Platform Length* | |||

|---|---|---|---|---|---|

| kg | lbs | mm | in. | mm | in. |

| 400 | 880 | 1050 | 41 | 1450 | 57 |

| 500 | 1100 | 1150 | 45 | 1550 | 61 |

| 600 | 1320 | 1250 | 49 | 1650 | 65 |

| 700 | 1540 | 1350 | 53 | 1750 | 69 |

| 800 | 1760 | 1450 | 57 | 1850 | 73 |

*Length is with use of cow trainers. If no trainers are used decrease stall length by 100 mm (4 in.). Ontario Department of Agriculture. http://www.fao.org/home/en/

Figure 7. A freestall barn with proper

ventilation and fans for air movement.

Freestalls that are well designed can reduce excessive standing, and minimize injuries. Many freestall barns start out as bedded-pack barns until enough capital is saved to add freestalls and freestall alleys. Freestall barns evolved from bedded-pack barns to reduce bedding costs and the amount of labor spent on bedding management.

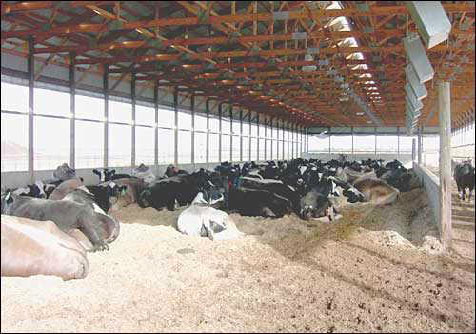

Figure 8. Bedded-pack barns provide a

comfortable resting place; however,

consistent daily management is needed.

Bedded-pack barns are a low cost alternative to freestall barns (Figure 8). However, the lower initial investment for bedded-pack barns may be offset by higher annual costs. Bedded-pack barns require careful and consistent daily management to create a healthy and comfortable cow environment. Poorly managed bedded packs canquickly turn into a sloppy, wet manure mess if not cleaned daily.

Summary

While improving your ability to handle cattle efficiently and safely does cost both time and money, it is an investment that provides an excellent and often immediate return. A number of options are available if you want to install a new facility or improve an existing one, enabling you to shape your facility so that it meets your needs without exceeding your resources.

Note As a rule, cattle can stay on pasture during the warm weather months.

Note A one or two-sided structure with a roof can provide shelter to heifers during periods of intense cold. Structures should be built with the open sides facing the south or east (depending upon prevailing winds) to maximize effects of solar radiation during the winter.

Note Cattle on average can consume 1 gallon of water per 100 pounds live weight per day.

Resources

Anderson, N., and J. Rodenburg. 1999 Designing for Cow Comfort in Tie Stalls. Agdex #729/410. Order #99-003. Government of Ontario. Ministry of Agriculture and Food. Source

Penn State, Agricultural and Biological Engineering Department

246 Agricultural Engineering Bldg. University Park, PA 16802. Ph:(814)865-7685 FAX:(814)863-1031 https://abe.psu.edu/

(Fact sheets and Idea Plans are listed under "Our Publications")

Graves, R., McGarland, D., Tyson, J. Designing and Building Dairy Cattle Freestalls. G-76. Penn State, Agricultural and Biological Engineering Department. https://extension.psu.edu/animals/dairy/health/facilities/designing-building-dairy-cattle-freestalls

Gay, Susan, W. 2009.Bedded-pack Dairy Barns.442-124. Virginia Tech Cooperative Extension. https://pubs.ext.vt.edu/442/442-124/442-124.html

For more information visit the UMass Extension Crops, Dairy, Livestock & Equine Program

Factsheets in this series were prepared by, Masoud Hashemi, Stephen Herbert, Carrie Chickering-Sears, Sarah Weis, Carlos Gradil, Steve Purdy, Mark Huyler, and Randy Prostak, in collaboration with Jacqui Carlevale.

This publication has been funded in part by the Massachusetts Department of Agricultural Resources and the Massachusetts Farm Bureau Federation, Inc.