Infiltration

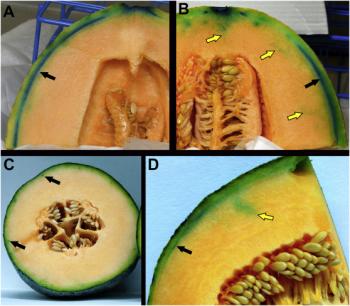

When produce is precooled using dunk tanks, it is possible for water to be drawn into the produce through a process called infiltration. Infiltration occurs when warm produce is placed into cold water. The cold water causes air pockets within the produce to contract, creating a pressure differential that pulls water into the produce. If dunk tank water is contaminated, microbes can be drawn into the produce along with the water, thus contaminating the inside of the produce. Infiltration is primarily a risk with dunk tanks that use recirculated water, as bacterial loads can accumulate quickly in such water. Infiltration is particularly likely to occur in apples, melons, peppers, and spinach.

Infiltration of human pathogen Listeria monocytogens, accompanied by blue dye for visualization, into cantaloupe pulp after hydrocooling. Source: Macarisin et al. 2017.

Factors that affect infiltration rates include:

- Temperature differential between water and produce (larger differential = more infiltration)

- Depth of water (deeper water = higher water pressure = more infiltration)

- Time produce spends in water (longer time = more infiltration)

- Produce wounding, including stem scars.

- Maturity of produce (green tomatoes are more likely to take up water than pink or red fruit)

Infiltration has recently become a topic of conversation because of its inclusion in the Food Safety Modernization Act Produce Rule, where growers are required to monitor the temperature of their produce wash water and maintain it at a temperature that will minimize the potential for infiltration. Before FSMA, USDA-GAP, the national voluntary food safety certification program, also required that recirculated dunk tanks be maintained at temperatures appropriate for the commodity, including to minimize the risk of infiltration.

In order to control infiltration solely by controlling water temperature, growers would need to keep dunk tank water temperatures warmer than produce temperatures, which would prevent dunk tanks from being used for precooling produce. Instead, the easiest ways to minimize the potential for infiltration are by controlling other factors that affect the process:

-

Minimize the amount of time warm produce spends in cold dunk tank water

-

Use sanitizers in your water. For more information, see the Produce Wash Water Sanitizer fact sheet.

-

Avoid using deep dunk tanks.

-

Pre-cool produce using methods other than dunk tanks, for example spraying or forced-air cooling.

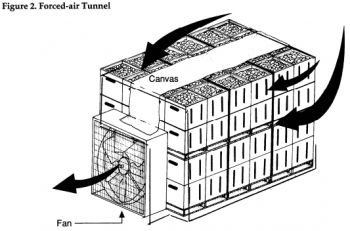

Forced-air cooling is a system in which boxes of produce are stacked up in parallel rows in a cold room, and a tarp is run across the aisle between the rows. Cold air from the room is pulled through the boxes of produce and the resulting warm air is pushed out with a blower. Forced-air cooling systems can be implemented on small scales and cool produce 75-80% faster than simply placing field-temperature produce in a cooler.

For more information on forced-air cooling:

North Carolina State Extension - Forced-Air Cooling

Forced-Air Cooling Systems for Fresh Ontario Fruits and Vegetables

Sources:

- Post-harvest Water and Use of Sanitizers – Virginia Cooperative Extension

- Introduction to Postharvest Water Disinfection Management - Trevor Suslow, University of CA, Davis

- Water and Pathogen Infiltration into Tomato Fruit – P. R. Gilreath, J. E. Bartz, J. W. Scott, and S. A. Sargent, University of Florida

- Macarisin, D., Wooten, A., De Jesus, A., Hur, M., Bae, S., Patel, J., Evans, P., Brown, E., Hammack, T., and Chen, Y. 2017. Internalization of Listeria monocytogens in cantaloupes during dump tank washing and hydrocooling. International Journal of Food Microbiology 257: 165-175. https://doi.org/10.1016/j.ijfoodmicro.2017.06.018

The Center for Agriculture, Food and the Environment and UMass Extension are equal opportunity providers and employers, United States Department of Agriculture cooperating. Contact your local Extension office for information on disability accommodations. Contact the State Center Director’s Office if you have concerns related to discrimination, 413-545-4800 or see ag.umass.edu/civil-rights-information.