Food Safety Plan

As you begin to develop your product for sale, remember that customers trust that you are preparing a safe, quality food. Steps toward manufacturing a safe product must be taken at each part of the development stage all the way to the customer.

Throughout the production of food there are many points when the integrity and quality of the product can be jeopardized. There are several opportunities for food contamination. A smart operator anticipates these risks, identifies the food safety hazards and makes a food safety plan outlining a course of action to reduce and eliminate these risks.

Before getting into the categories of the food safety plan; you need to know that although it is regulatory required there are many benefits to having a solid food safety program. A few examples would be a decrease potential for recalls, a safe food product, a higher quality and yield, a greater likelihood of meeting buyer requirements and more!

Food Safety considerations should be assessed in 3 categories:

- Biological- pathogens or organisms that can cause harm to consumers

-

Chemical- substances that exist in a food or environment that can cause harm to consumers (such as allergens, cleaning agents, pesticides, or heavy metals)

-

Physical- any extraneous material that can cause harm to consumers (such as broken glass, plastic particles, insects, metal filings)

By thinking about potential hazards throughout the development cycle, you will be better equipped to navigate food safety risks within your produce and work towards a safe product.

Pre-Development: Before you begin developing your product, try to prevent any food safety risks. A few considerations should include:

- Choose an appropriate production facility

- Choose an appropriate process for the intended product

- Anticipate process and formula hurdles

- Observe set regulations and validation procedures

Development: On the development end there is an arsenal of techniques that a producer has to target biological contamination. This includes key formula hurdles such as:

- pH Regulation- Many bacteria grow best in a relatively neutral pH environment. Adjusting the acidic character of your product through the addition of acid or by other means can prevent such bacteria from surviving in the food and potentially infecting consumers. Every pH meter operates slightly differently, so be sure to follow your manual to operate correctly. For more information, check out University of Wisconsin- Using and Calibrating a pH meter.

-

Water Activity- Water Activity is a measure of the amount of “free” water in a product. The level of activity can impact product quality, shelf life and safety. Bacteria, like humans, require water to survive. Methods to reduce water activity include the physical removal of water through evaporation, dehydration, and freezing. Adding salt or sugar to a product chemically reduces water activity by binding up the “free” water, leaving little for the bacteria, preventing them from having a suitable environment to grow in. Gor more information, check out UC Davis- Quick Guide to Water Activity.

-

Processing Temperature and Time- Just as humans cannot stay out in the sun for too long without getting sunburned, bacteria cannot survive certain conditions without damage. Maintaining a certain temperature for a specific time incapacitates bacteria and other pathogenic cells. Unable to grow in the food, they eventually die and are no longer a risk for illness. This sensitivity allows food processors to create Critical Control Points (CCPs). These are thresholds for your product to ensure that bacteria will not survive. A processor will set these points in advance then monitor and continue to heat the product until they are met.

Depending on the food product you’re making, some of these management practices may not be useable. To ensure the safety of your product, it’s recommended that you have multiple practices to manage bacterial growth, to create hurdles that make growth for bacteria difficult.

Processing Temperature and Time- Just as humans cannot stay out in the sun for too long without getting sunburned, bacteria cannot survive certain conditions without damage. Maintaining a certain temperature for a specific time incapacitates bacteria and other pathogenic cells. Unable to grow in the food, they eventually die and are no longer a risk for illness. This sensitivity allows food processors to create Critical Control Points (CCPs). These are thresholds for your product to ensure that bacteria will not survive. A processor will set these points in advance then monitor and continue to heat the product until they are met.

Most processors combine the use of these three techniques to develop a safe product and process.

Production- Arrange procedures to ensure quality and safety before, during, and after production to ensure you and your staff are following the intended method of production, ensuring a safe and quality product.

- Pre-Requisites: Certificate of Analysis of incoming ingredients

- Good Manufacturing Practices

- Personnel Training: product quality thresholds, process checkpoints, cleaning and sanitizing protocol, record-keeping, batch size optimization for equipment and production rate, process timing

- Operational Limits- Quality Control/Quality Assurance checks

Formal Plans- HACCP, Preventative Controls

Be aware of the steps ahead: Figure 2- Chart of Regulations, gives a brief, non-exhaustive list of some common food product categories and key paperwork and registration required.

| Product | Residential Kitchen | GMPS | USDA | FDA | ||||

|---|---|---|---|---|---|---|---|---|

| Register with State FPP if Wholesale | Registration | HACCP | Registration | HACCP | Form 2541, 2541a |

Process Authority | ||

| Acid Foods - Vinegar | X | X | ||||||

| X | X | X (Scheduled Process) |

X | |||||

| Baked Goods (Non-PHF) | X | X | X | |||||

| Canned Meat Foods | X | X (if more than 3% meat) |

X | X | X (If more than 3% meat) |

|||

| Dairy | X | X | X | |||||

| Fermented Food | X | X | ||||||

| Frozen Entrees | X | X | ||||||

| Jams and Jellies | X | X | ||||||

| Juice | X | X | X | |||||

| X | X | X | X | |||||

| X | X | X | X | |||||

| X | X | X | X | |||||

To Summarize:

- All food processors must follow Good Manufacturing Practices as stated in the Code of Massachusetts Regulations and the Code of Federal Regulations.

- In general:

- FDA regulates the production of all food products

- USDA regulates meat and poultry products

- HACCP plans are required by the government for juice, seafood meat, and poultry products. However, some consumers (buyers) may require a food safety certification in order to become an approved vendor.

- Additional forms and paperwork are required for shelf stable canned goods such as form 2541 and 2541a for canned goods, and process authority approval

NOTE: A product containing meat or meat products above 3% falls under jurisdiction of the USDA.

Additional regulations regarding the sale, slaughter, and grading of meat must be followed. For more clarification about which business will have to register with the USDA, observe this table from the Investigations Operations Manual.

Facility

Residential Kitchen

Are you considering making your product in your home?

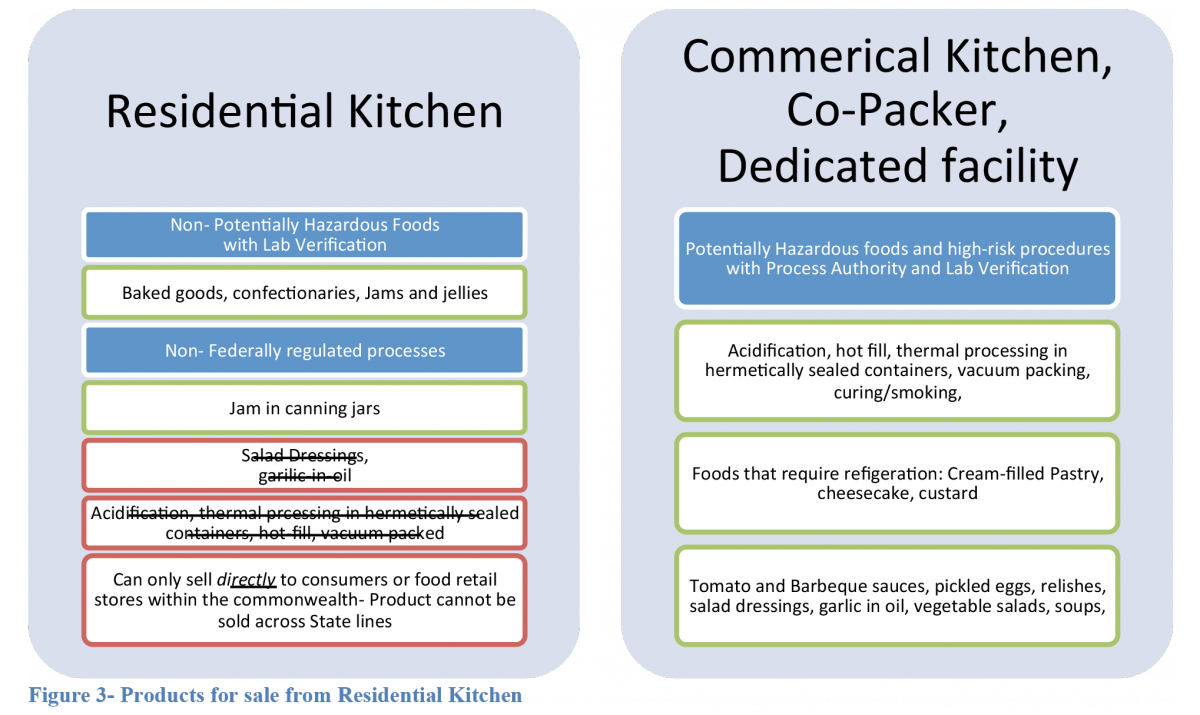

The state of Massachusetts allows for the preparation of Non-Potentially Hazardous food (PHF) products in the home. In Massachusetts regulation this is referred to as a Residential Kitchen.

The state limits which products can be produced in the home and from which processes. A PHF food is defined as one which is capable of supporting the rapid growth of infectious microorganisms without additional temperature control. For instance, the cream filling of a cannoli without refrigeration can support the growth of bacteria such as salmonella. As such, it is considered a PHF and requires a temperature control: refrigeration.

In the state of Massachusetts, non-dairy baked goods, confections, jellies and jams can be processed in residential kitchens.

Products produced in a residential kitchen cannot be sold over state lines or over the Internet because they are not federally recognized as safe. Before any food produced in the facility can be sold, a Residential Kitchen must be licensed by the Local Department of Public Health.

Consult the following table (from MDAR Residential Kitchen Brochure) and FAQ page on the MDAR Resource Guide for more about what can and cannot be made in a Residential Kitchen.

In order to be licensed, the kitchen must follow Good Manufacturing Practices for food and food handling:

- Code of Massachusetts Regulations 105 CMR 500.000

- Code of Federal Regulations 21 CFR 110.000

These are the same rules for commercial kitchens, restaurants, and other food businesses.

Also note that a wholesale residential kitchen will have to follow the same regulations and licenses for a wholesale food business (see previous section).

Other Facility Options

Owners of businesses with products that cannot be produced in the home have several facility options. Each of these options comes with its own costs and benefits.

Choosing which option is best for your business can be decided with the development of your business plan. Before you make a decision, you must simultaneously consider the cost to your business, as well as regulations for your product and desired process. Can this facility adequately fill your specific needs? Below is an outline of a variety of facility options you can consider to determine your options for manufacturing.

- Commercial Kitchen

- Produces food as a business - a restaurant, school or church kitchen

- Licensed by the state and municipality to adhere to all food facility regulations

- Your business will have to apply for its own license for the space

- You will need to rent use of the equipment and complete all of the labor yourself

- Time of availability may be for off-peak hours

- Start your search: “Rent Commercial Kitchen”

- http://rentthiskitchen.com/

- http://www.cookithere.com/

- http://www.commercialkitchenforrent.com

- Ask local churches, restaurant,s or community clubs (i.e. Elks lodges or VFW) if they are a licensed facility and if their kitchen is available for business development purposes

- Questions to ask:

- Are there any minimum requirements for rental?

- What is the rental rate? Pay by hour or day?

- Are there any required certifications? (Sanitation certificate)

- Will I be sharing the space with any other groups during my rental?

- Do you require insurance?

- What materials are available for use during rental time?

- What storage options are there? How much space is allowed? How much will it cost?

- Shared Use Kitchen

- A shared commercial kitchen specifically for small businesses such as caterers,

- food trucks, and producers

- Businesses sign up for a time slot to use the space

- Often competitive

- Have to pay for time use of equipment and storage

- Complete all labor yourself

- Start your search for a shared use kitchen at the New England Food Entrepreneurs page

- Food Business Incubator

- Comprehensive facility for sprouting small businesses

- Consultation on the entire food business process from business management to product production

- Commercial and industrial sized equipment for production and packing

- Membership required, often for a fee

- Additional fees for the type and scale of your product, the time and equipment you use in their kitchen

- May contract as a co-packer

- Listings:

- Co-Packer

- A licensed facility that produces your product for you according to provided specifications

- Good for products requiring specific equipment, small or infrequent runs

-

A list of Co-Packing businesses can be found under Resources

-

Note: The capacity of commercial kitchens, shared use kitchens, food businesses incubators, and co-packers will vary significantly from business to business. It’s crucial to do your research and talk with operators when deciding what facility is best for your operation.