Germination Chamber/Growth Room for Seedling Production

Providing the optimum environment can decrease germination time, improve uniformity and increase the number of seeds that germinate. Germination carts and growth rooms are used by growers to provide this environment and get the seedlings off to a good start.

Factors for Germination

Critical factors for germination include moisture, oxygen, temperature and light. Seeds from the packet are at 4 – 12% moisture content. To germinate this needs to be increased to 25 to 50%. Select a growing media that has good water holding capacity, adequate drainage and allows good contact with the seed. Some growers have found that seed priming, partially hydrating the seed first, will give more uniform germination.

Temperature is also important. Extensive testing by USDA and several universities has found that each species has a range of temperature that is best for germination. For some such as Marigolds, almost complete germination will take place at any temperature between 50°F and 85°F. Others have a much narrower range, such as Freesia that germinates only between 55° and 65F.

Light requirements vary with the species. Some seeds require it, some don't and some don't care. Some seeds are pretreated with light before they are sold. Once germinated, adequate light to prevent stretching is important.

Fluorescent lamps are the common choice for providing the light needed if you are going to grow the seedlings on after germination. Install strip fixtures evenly over the growing area. T-8 fluorescent lamps are most common and are usually more cost effective than T-5's. Cool white or a mixture of cool white and warm-white work best. The fixtures can be mounted horizontally above the plants. The new LED lights are becoming popular for germination and propagation. Some manufacturers such as Phillips Lighting have developed fixtures with a light spectrum specific to a particular crop. The cost of the fixtures is decreasing fairly rapidly. Electricity use is about 35 watts for a LED fixture as compared to about 30 watts for a single tube, T-8 fixture.

Seed companies are good sources for providing the optimum environmental requirements for the different cultivars and species.

Germination Carts

Although many growers germinate their seed in a greenhouse, a germination cart, or room will provide a better environment. In addition, it will save energy by not having to start the greenhouse for a couple of weeks during the coldest part of the winter.

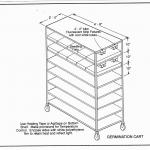

Building or purchasing a multi-tray germination cart is an inexpensive way to get the proper environment (Figure 1). Movable shelves provide space for different size containers. A thermostatically controlled electric heat tape installed on the lowest level will provide the heat. Enclosing the cart with clear polyethylene or double wall polycarbonate will retain moisture and heat. Commercial models are available from greenhouse suppliers.

By spacing the shelves 12" - 18" apart and hanging fluorescent strip fixtures underneath the shelves the germinated seeds can be left to grow for a couple of weeks before moving to the greenhouse. This saves energy by not having to start the greenhouse. A light level of 25 to 35 lamp watts/sq ft of fluorescent light is adequate for most seedlings. USDA research has shown that the initial optimum growth rate continues for a period after the seedlings are moved to the greenhouse.

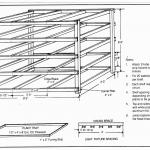

Growers that need more space usually set up a growth room. This separate insulated room has heat and ventilation to keep the temperature and humidity at the ideal level. The room is usually set up with fixed shelves spaced 15 to 18 inches apart to allow room for fluorescent lights and the seed trays (Figure 2). Shelves should be sized to best utilize the space and lighting. To eliminate the need for benches, some growers place the seed trays on carts and move the carts into the room. This makes handling more efficient.

For germination only, a thermostatically controlled electric heater will provide the heat needed. In a larger room, a unit heater will be less expensive to operate. Heat requirements will depend on the level of insulation provided. Air circulation from a small fan will help to keep the temperature uniform and reduce dead spots.

If lights are used, they will provide more than enough heat to keep the temperature above 70°F. During the cool season, excess heat can be vented with a small exhaust fan and intake louver. During warmer seasons, refrigeration may have to be used. One way to lower the heat load is to stagger the lighting by operating half the lights for 12 hours and the other half for the other 12 hours. Excess heat could also be ducted to an adjacent greenhouse or headhouse area.

Wall and ceiling surfaces should be painted with a white acrylic paint to provide a reflective surface that can be washed down easily. The floor should be painted and have a drain for water.

The electrical system should have adequate capacity for the lights, heat and fan. Total up the wattage of the equipment that could be on at the same time. Due to the possibility of nuisance tripping, ground fault circuit interrupters (GFCI's) are generally not required. It is better to connect all equipment to a good grounding conductor that is run with the circuit wires. It is also desirable to install high-low temperature and power-off sensors to the alarm system.

A germination room must be tight to retain moisture and keep a high relative humidity. After an initial, through wetting, flats can be irrigated by hand with a mist nozzle. A humidifier could be installed to add moisture to the air. A relative humidity of about 95% is recommended to maintain growing media moisture levels.

Seed germination and growth to transplant size are usually the most critical stage of plant development. Providing an optimum environment with a germination cart or growth room will give uniform high quality plants in less time.

John W. Bartok, Jr., Extension Professor Emeritus & Agricultural Engineer

Department of Natural Resources and the Environment, University of Connecticut, Storrs CT – 2015