Cranberry Irrigation Management (2004)

Cranberry Irrigation Management

Hilary Sandler, Carolyn DeMoranville and Bruce Lampinen Cranberry Station, University of Massachusetts Amherst

IRRIGATION AND DRAINAGE

When required, irrigation can be supplied by either subirrigati on or overhead sprinklers, or by both in combination. When irrigating primarily with overhead sprinklers, the driest areas will tend to occur on the edges of beds and the wettest areas at the center of the bed. Many commercial beds are irrigated primarily by sub-irrigation. Sub-irrigation is accomplished by maintaining a water table beneath the root zone and allowing the process of capillary rise to move water up into the root zone. Work at the State Bog in 1998 and 1999 has shown that substantial amounts of water can be provided to the root zone by capillary rise from water tables at depths of up to 18" below the root zone. Capillary rise was observed to lift water more than 24" high on some cranberry beds, but it is essential to know the characteristics of your individual bed before assuming that capillary rise will be adequate to meet crop water needs. When irrigating primarily by subirrigation (and refilling ditches on a regular basis), the wettest areas will tend to be near the ditches and the center of the bed will most likely be the driest.

Regardless of the irrigation method used, it is critical to maintain adequate drainage across the bed to prevent waterlogging in the root zone.

Water management is important in disease management as well. Excessively wet soils increase the likelihood of Phytophthora root rot, while excessively dry soils can promote fairy ring disease. It is important to remember that as with nutrients, the impacts of water management in the current year can be manifested in both the current and subsequent crops.

Sub-irrigation: Sub-irrigation is accomplished by maintaining a water table beneath the surface of the bed throughout the growing season. Maintaining water in the ditches at a level about 18" below the bed surface is an essential component of this method. Capillary rise from a water table beneath the surface of the bed can meet a substantial portion of cranberry water needs under many conditions. In a typical cranberry bed in Massachusetts, water can move up from a water table located -18" below the soil surface at a sufficient rate to meet plant needs under normal conditions. With water tables deeper than 18" or under high evaporative demand conditions (hot and dry), capillary rise may not be adequate to meet plant demands. It is essential that you know the characteristics of your individual bed before attempting to irrigate primarily by capillary rise. The height of capillary rise will vary from bed to bed with finer textured soils. Beds with higher organic matter contents will tend to have higher capillary rise. Since soil conditions and contours of beds vary, you must be certain that water is moving at an adequate rate up from the water table into the root zone as well as horizontally across the bed to meet the water demands of the vines at the center of the bed.

Water level float - A simple way to monitor the water level in the center of the bed is with a water level float. The water level float consists of a fiberglass rod attached to a float that rides on the water table in a fabric-wrapped perforated pipe. Water floats are very advantageous because you can easily see the level of the water table without walking onto the bog. Instructions for constructing a water level float are available from the UMass Cranberry Station. If the bed is substantially out of grade, you may want to place a tensiometer at the high point and a water level float at the low point of the bed. By comparing the water level in the center of the bed (as indicated by the water level float) to the water level in the ditches, you can assess whether water is moving across the bed at a fast enough rate to meet the water demands of the vines. If the water level in the center of the bed is adequate while the ditch level has dropped too low, you can pump up the ditches without running the overhead irrigation system (presuming your irrigation system is set up to allow this). If the water level in the center of the bed is too low, you can run the overhead irrigation system. By observing the water level float through several irrigation cycles, you can determine the number of hours required for an adequate irrigation.

| Irrigation | Middle | Edge |

| Overhead | Wetter | Drier |

| Sub-irrigation | Drier | Wetter |

Tensiometer - A tensiometer in the center of the bed can serve the same purpose as the water level float. A tensiometer has the advantage of registering a midday drop in tension as the water table drops near the level at which capillary rise can no longer keep up with plant water demands. The disadvantages of a tensiometer include the fact that they are sensitive to freezing damage and you need to walk out on the bed to take a reading. Tensiometer readings are normally expressed as centibars (cbars) of tension. Low numbers indicate wet conditions; high numbers indicate dry conditions (Table 1 ).

A tensiometer reading of Oto 2 cbars in the root zone indicates that the water table is too high and that damaging, anaerobic conditions may be occurring (Table 1 ). With a water table present, the reading on the tensiometer should be in the 2 to 5 cbar range as long as the water table is between 8" and 18" below the surface. As the water table drops below 18", the soil can dry substantially at mid-day (water supplied by capillary rise lags behind the water demands of the plant). Because of this mid-day drop in tension, it is best to read your tensiometers at midday as well as (or instead of) in the morning. A midday tensiometer reading above 10 cbars in the root zone indicates that the water level is too low to supply water by capillary rise; irrigation should be initiated the following morning. A substantial difference (greater than 3 to 5 cbars) between morning and midday tensiometer readings is a good indication that capillary rise is not able to keep up with plant water needs at midday.

Sprinkler irrigation: It is important to monitor soil water conditions to schedule irrigation efficiently. When irrigating primarily by sprinkler, the driest areas will tend to be near the edges of the bed while the wettest areas will tend to be near the center (Figure B, page 3). Therefore, you should monitor soil moisture ( and or water table level) both near the edges of the bed (approximately 5 to 10 feet in from ditch) as well as in the center of the bed. A water table depth more than -18" below the surface or a middaytensiometer reading higher than 10 cbars indicates that irrigation is needed. When irrigation is required, the sprinkler system should be run early in the morning rather than in the evening. Vines can get watered with minimal evaporation, and the surface of the vines ( and fruit) can dry out in the sun's heat. When the sprinkler system is run in the evening, the vines remain wet for an extended period, thus creating favorable conditions for infection by the fruit rot fungi. It is important to do regular tensiometer readings. This helps you avoid situations where midday readings indicate the soil requires immediate irrigation. By monitoring the tensiometers on a daily basis, an irrigation can be initiated immediately when a morning reading rises above about 5 cbars. As an alternative, you can read the tensiometers at midday and initiate irrigation when the midday reading is above about 1 0 cbars. Ideally, if you monitor the tensiometers in the morning and again at midday, you can initiate irrigation (the following morning) when the morning and midday tensions begin to deviate by more than -3 to 5 cbars.

Combined sub and sprinkler irrigation: Water use efficiency can often be maximized by combining sprinkler and sub-irrigation. This can best be accomplished by monitoring soil moisture using tensiometers and/or floats at both the center of the bed and near the edge of the bed (about 5-10 feet from the ditch). Using this method, sprinkler irrigation is initiated if the soil moisture in the center of the bed reaches critical levels (see previous float and tensiometer

| Morning tension (cbars) | Midday tension (cbars) | Water table level** (in. below surface) | |

| Too wet | 0 to 2 | 0 to 2 | 0 to 6 |

| Adequate | > 2 to 5 | > 2 to 10 * | > 6 to 18 ** |

| Too dry | > 5 to 80 | > 10' to 80 | > 18 ** |

- Adequate range for midday tension in mineral soil and dry beds is 2 to 8 cbars in normal conditions and 2 to 6 cbars under high evaporative demand conditions as discussed on page 3.

- *may vary based on soil texture, soil organic matter content, initial rooting depth, etc. (see section on rooting depth, page 3, for more details).

sections for details). If the center of the bed has adequate water but the ditch water level drops too low (more than 18" below surface of bed) or the soil moisture near the ditch is too low, the ditch water level can be pumped up. Combining ditch flooding and sprinkler irrigation worked well at State Bog in 1999-2000 and allowed the average sprinkler irrigation interval to be about every 5 to 6 days. The interval could be extended during rainy periods.

Drainage and water table management: Drainage is extremely important to cranberry production. By providing adequate drainage early in the season, you should be able to improve rooting depth and productivity. As described above, a water level float or tensiometer will give you an indication of periods when the water level is too high in the center of the bed. Any time the water level in the perforated pipe is closer than 8" from the surface, an attempt should be made to lower ditch water level to improve drainage. With the tensiometer, a reading of Oto 2 cbars indicates that drainage needs to be improved.

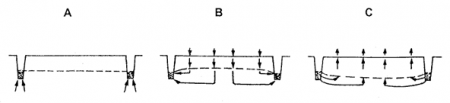

It is important to remember that the level of the water table beneath the surface of the bed is not necessarily flat. Figure A (below) shows the equilibrium situation when drainage has ceased and the ditch water level and the water table across the bed are even. Figure B shows the situation after sprinkler irrigation or a rainfall event when the level is higher in the center of the bed. It can take 1-3 days for water to drain from the center of the bed to the ditches depending on soil characteristics and the ditch water level. If you are using sprinkler irrigating every 3 days or less, you may always have a higher water table in the middle of the bed than near the ditches. Figure C shows the situation (after subirrigation) where the vines have drawn down the water table in the center by using water at a higher rate than can be replenished by lateral movement of water across from the ditches to the center of the bed. This situation indicates that sprinkler irrigation is needed to replenish the water in the center of the bed.

Rooting depth: One important long-term goal of water management in cranberry is to improve rooting depth. Keeping the bed well drained and minimizing the time that water is standing in or near the root zone encourages root growth. Increased root growth leads to increased access to water and nutrients and decreased likelihood of drought related damage. Root depth can be increased by gradually lowering the water table over a number of seasons. During the process of lowering the water table, it is essential to monitor rooting depth and soil moisture in the root zone to prevent any water stress related damage. You should lower the tensiometer cup deeper into the soil as rooting depth increases to more accurately reflect the moisture content in the root zone. In so doing, remember that the data in Table 1 is based on a shallow root zone (down to -3") as is commonly found in MA cranberry beds. In this situation, the ceramic cup on the tensiometer would be just below the soil surface. Remember that if the root zone extends substantially below the 3" level and the tensiometer cup is substantially lower, the level of the water table shown in Table 1 should also be lowered a corresponding amount. The markings on the water level floats should also be changed to correspond to the new rooting depth.

Special caution for mineral soil and dry beds: For beds where a water table is not maintained below the surface, proper irrigation scheduling is even more critical. Tensiometers placed so that the ceramic cup is in the root zone can be a useful tool. It is essential to locate a tensiometer in the driest part of the bed to help predict when water stress related damage could occur. Under high evaporative demand conditions, water stress related damage has been observed on MA mineral beds when the midday tension reading (the day before the damage occurred) in the root zone was less than 10 cbars. Therefore, when a water table is not maintained below the surface, you should monitor midday soil moisture tension and schedule an irrigation (for the following morning) when the midday tension reaches about 8 cbars in the root zone. When high evaporative demand conditions are predicted (hot, windy weather), you should schedule an irrigation (for the following morning) when the midday tension reaches about 6 cbars in the root zone.

Extreme conditions: During periods when temperatures are predicted to be excessive, it is important to have the vines fully watered before the hot conditions arrive. Based on research done in New Jersey, conditions that require you to pay particular attention to proper irrigation are ( 1) air temperatures of 80° F or more (2) dewpoints of 55° F or less during midday and afternoon hours, (3) clear or scattered sky conditions during the day, (4) wind speeds average greater than 11 mph, and (5) no rainfall has occurred during the last 48 hours. When the above conditions are present, particularly in newly planted beds and on mineral soil beds, you should monitor soil moisture in early morning and again in late morning to assure that adequate moisture is present in the root zone. If moisture is inadequate, sprinklers should be run for 1 to 2 hours in the late morning or early afternoon to replenish the soil water. This will also help to cool the vines and berries.

IRRIGATION SYSTEMS

INSPECTION. Systems should be cleaned and inspected each year. Check packings, seals, and foot valves. Inspect all welds and connections for pinholes, pitting, and leakage. Inspect nozzles for excess wear and replace worn ones. An expansion of 1/64" will increase water use by 1 gallon per minute per head. When possible, use high uniformity nozzles. Measure several risers on your acreage to get an idea of the average height. Strive to make all of your risers approximately 18" tall. Additional system upgrades may include staking risers (they should be plumb) and fixing saddles. The pressure at the weakest head should be no less than 40 psi.

Requirements for Chemigation through the Irrigation System: (see definitions, page 6.)

- If the discharge piping is at least 2' higher than the top ot the highest sprinkler head, install a vacuum breaker (anti-siphon) at the highest point of the disch arge piping. Install a 3/4" injection port with a check valve at least 6" lower (downstream) and install a 1 /2" interlock port before the injection port.

- If the discharge pipe is less than 2' higher than the top of the highest head, install a chemigation check valve on the discharge pipe. This unit contains a check valve, vacuum breaker (anti-siphon), injection port, interlock port, and low-pressure drain.

- Restricted chemicals can no longer be drawn into the suction side of the pump. They must be injected (using a pump or venturi) into the pressure side of the running irrigation pump.

- If a pump is used, it must be a positive displacement, non-impeller type ( diaphragm or roller) and must have a chemigation suction line check valve, a low-pressure interlock and a discharge hose connection to the injection port. The pump may be powered by electric or gas engine. If a venturi is used, connections are made before and after a mainline throttling valve and requires a check valve on its chemical suction line.

IRRIGATION UNIFORMITY. Performance of your irrigation system should be optimized each year prior to using chemigation as a pesticide application technique. Uniform application is important not only for chemigation purposes, but also to maximize frost protection and water delivery to the vines throughout the season.

The actual layout of the sprinkler system will affect uniformity as well as wash-off and rinse times. For chemigation purposes, a 40' x 50' spacing with high uniformity nozzles in an "H" pattern delivers the most uniform application. However, other designs will certainly provide effective application. Numerous factors can affect the uniformity of application. A catch-can test can be conducted to determine the Coefficient of Uniformity (CU) of your system. Fact sheets with instructions on how to conduct a CU test are available from the UMass Cranberry Station.

Do everything possible to improve the Coefficient of Uniformity (stake and straighten risers, etc.) of your present system. If you are in the position of installing a new system, be sure to take advantage of the new technology and information that is available. Systems should be designed to maximize the CU as much as possible and to minimize the wash-off time (time from fit head tolasthead).

TRAVEL TIME THROUGH THE IRRIGATION SYSTEM.

Timing your irrigation system is extremely important. It directly affects the level of pest control you can obtain by chemigation. Establishing a rinse-out time can be done by running a concentrated dye solution through your system. Dye tests should be run every 1 to 3 years. You should certainly run a dye test any time significant modifications are made to your irrigation system.

- Wash-off time= Rinse time - travel time

Definitions:

Injection port to first head (travel time). This is the time needed for the material to actually reach the bog.

Injection port to last head (rinse time). This refers to the time, measured from the end of the injection, that it takes a chemical to clear the last head in the system. This is the length of time you will run the irrigation system after the chemigation injection is completed.

First to last head (wash-off time or travel time on bed). This is the time that water (without any chemical) is being applied to the vines (traveling from first head to the last head). Long wash-off times will dilute and wash the material from the target area (leaves or fruit). You should try to get the wash-off time to be as short as possible (5 minutes or less).

Goals of a dye test are to:

- Determine how long to operate the chemigation application, and

- Observe mixing and application performance.

Running a dye test:

- Locate the first head in the system that applies water.

- Mix a concentrated solution of tracer dye (e.g., 1 oz per acre in a gallon of solution). Novice timers may want to use a darker solution since it is easier to see as the dye moves through the system.

- Place the gallon of mixture in the spray tank and inject it through your chemigation system. It will be necessary to circulate the mixture for a few minutes to fill the injection hose.

- Using a stopwatch or a watch with a second hand, start timing as soon as you start to inject the solution. Do this as quickly as possible. Try to inject the dye solution in 15 to 30 seconds. This will give you the maximum time to observe your system as well as give you a dark solution. Clean up and rinse out equipment later. You will be wasting excellent observation time by cleaning at this point.

- Note the time it takes for you to first see dye reach the first head and last head. The last-head time minus the first-head time is the wash-off time (see below). This is the amount of time the system will be "washing off' the applied material.

If you note differences in the dye concentration (i.e., some sprinklers are darker than others) as it moves through your system, the chemicals may not be mixing enough before they reach certain lateral lines.

In general, the shorter the wash-off time (the time from first to last head), the better. You should target washoff times to be as low as the system will allow. The efficacy of newer reduced-risk insecticides can be higher with wash-off times around 2 to 3 minutes. Unless your pump house is a significant distance from your bog, excessive rinse times (from the pump to the last head) will adversely affect pesticide performance.

Even though you will strive to have as short a rinse time and wash-off time as possible, there may be certain instances where the performance of a material will be improved with a slightly longer rinse time (assuming that your normal rinse time is fairly short). For instance, fungicide applications on bogs with very thick vines may benefit from an increased rinse time.

INJECTION ISSUES. Injection time is the amount of time needed to inject the material into the irrigation system. This affects the dilution of the product that you are injecting. Typically, pumps run at 70 gal/ minute/acre. Most labels indicate that chemicals should be applied in 400 to 600 gallons of water per acre. Thus, a 6 to 8 minute injection should be your target injection time. Smaller pump systems should aim for 6 minutes; larger bogs should aim for 8 minutes. Extra-large pump systems (25+ acres) should allow an additional minute (9 minutes total).

Note that an injection time that is too short (less than 6 minutes) risks injury to the vines, particularly around the heads. Injection times that are too long for a given pump system risk losing efficacy of the product.

NEW TECHNOLOGY. Gear-driven pop-up irrigation heads have been introduced to the industry during the past few years. Pop-up heads are designed to be less labor-intensive and more economical. Other advantages include improved uniformity, ability to turn individual heads on and off, and decreased vandalism. Pop-up heads can be installed onto existing 50' by 60' or 40' by 50' layouts. Recent research at UMassDartmouth has focused on combining pop-up heads with automatic turn-on systems and remote monitoring of envionmental conditions. Growers considering renovation or significant re-vamping of established irrigation systems are strongly encouraged to also consider integration of this new technology into their farming operations.

CHEMIGATION DEFINITIONS.

Check valve. A valve that is used to allow the direction of flow to go in only one direction.

Interlock port. A port that is used to connect a line that goes to a low-pressure shut-off switch. If the pressure on the irrigation pump drops, the shut-off switch will stop the chemical injection pump so chemicals are no longer pumped into the irrigation discharge pipe.

Injection port. A port that connects the line between the chemigation pump and irrigation discharge pipe. This is the port into which the chemicals are injected. This port always has a check valve installed with it, so water cannot flow back towards the chemigation pump.

Low-pressure drain. The low-pressure drain is part of the chemigation check valve unit. This drain acts as a sump that catches any chemical that may leak past the check valve if the pressure drops.

Main line throttling valve. This valve is on the pressure side of the pump on the irrigation pump's main discharge line. An inlet line to the venturi is connected before the throttling valve and then the outlet line of the venturi is connected after the same valve. When the throttling valve is partially closed, this creates more pressure which is routed through the venturi. It causes a suction within the venturi that alows the chemicals to be drawn into the venturi through a suction line. Then the chemicals are injected into the main line through the outlet line of the venturi. The suction line of the venturi has to have a check valve installed so water does not flow back through the chemical suction line.

Vacuum breaker. A vacuum breaker is an anti-siphon device that breaks the siphon within the discharge line by allowing air to enter the discharge line when pressure is lost. This keeps the irrigation water from siphoning back towards the fresh water source.

Venturi. A venturi is a unit that consists of a pressure inlet, suction inlet, and an injection outlet. This unit is used in conjuction with a throttling valve. When the throttling valve in the main discharge line is partially closed, a higher pressure is routed through the venturi causing a suction for the chemicals to be drawn into the venturi. The higher pressure is then injected into the main discharge line on the other side of the throttling valve.

Dr. Bruce D. Lampinen

Current address:

Department of Pomology

University of California, Davis

References:

Lampinen, B. D. 2000. Construction, Installation and use of Water Level Floats. University of Mass. Publication.

Croft, P. J. 1992. Meteorological investigation and prediction of scald. Cranberries 56( 1 ):6-7, 18.

Croft, P. J. 1993. A conceptual model of scald. Cranberries 57(4):25.

*Special thanks to Steve Ward, Cranberry Growers' Service & Jack Heywood, Stearns Irrigation for contrib uting their knowledge & expertise to this fact sheet. **

February 2004. A product of the Cranberry Station, College of Natural Resources and the Environment, University of Massachusetts Amherst.

United States Department of Agriculture cooperating. UMass Extension provides equal opportunity in programs and employment.

Published by: Cranberry Station, University of Massachusetts Amherst, P.O. Box 569, East Wareham, MA 02538