In Our Spotlight

“We Can Turn Climate Change Around”

Peggi Clouston, Associate Professor, Environmental Conservation at UMass Amherst defines trailblazer. She makes a bold prediction: “Using much more wood in large-scale construction, with products like cross laminated timber (CLT), could help us to sequester enough carbon that we could actually turn climate change around.” Wow. And she has scientific data to back up this statement.

Talking with her for a few moments as she quickly educates her listener about how wood works, it is easy to become a believer in wood-framed commercial buildings, ditching the notion that they need to be fabricated solely with steel and concrete to be functional. Clouston contributes a passionate voice in this new building arena. She loves wood. “It’s sustainable. It’s high-tech. It’s beautiful and healthy. What more could you ask for?”

Environmental Conservation

Clouston makes a compelling case for timber (wood) construction of large non-residential buildings (dormitories, office buildings, schools, etc.) through the lens of environmental conservation. She has devoted her professional career to researching topics that innovate and foster structural use of wood and bio-based composites, topics such as: computer modeling of structural composite lumber, development of wood-concrete composite systems, mechanical evaluation of laminated veneer bamboo, and straw bale wall construction. She is enthusiastic about her research and is garnering increased esteem within the architectural and engineering communities through her recent role as Lead Investigator of a study which aims to utilize low-value Northeastern woods in cross laminated timber (CLT) panels like those used in the UMass Design Building’s floors. Think of CLT like a wood sandwich filled with Dagwood’s best ingredients. CLT is comprised of layers of lumber laid crosswise, then glued together. Because it is a composite, this means that lower quality woods, so abundant in the Northeast, offer real potential as a source of materials. The positive spin-offs of her study will mean a market for low value trees and will secure the health of local forests even as it creates green jobs for the forest industry in the Northeast.

The Design Building was originally designed to be just another steel-concrete structure on campus before Clouston and her colleague, Alex Schreyer, got involved. Partly a design intervention, Clouston and Schreyer, director of the Building and Construction Technology Program, persuaded local politicians, university officials and the design team to build the frame with wood as a demonstration structure for new wood technologies. Owing to the help of Former Massachusetts Congressman John Olver, a $3M contingency fund was secured in the 2014 State Environmental Bond Bill to cover potential cost overruns that could accrue from unfamiliarity of working with new technologies. Clouston proudly remarks that “now we have design professionals from all over the U.S. coming to UMass to learn how to build this way.” [PC1] Thanks to Schreyer, anyone with a computer can visit the construction site with his awe-inspiring 360 degree panoramas of the building’s construction process.

The Design Building was originally designed to be just another steel-concrete structure on campus before Clouston and her colleague, Alex Schreyer, got involved. Partly a design intervention, Clouston and Schreyer, director of the Building and Construction Technology Program, persuaded local politicians, university officials and the design team to build the frame with wood as a demonstration structure for new wood technologies. Owing to the help of Former Massachusetts Congressman John Olver, a $3M contingency fund was secured in the 2014 State Environmental Bond Bill to cover potential cost overruns that could accrue from unfamiliarity of working with new technologies. Clouston proudly remarks that “now we have design professionals from all over the U.S. coming to UMass to learn how to build this way.” [PC1] Thanks to Schreyer, anyone with a computer can visit the construction site with his awe-inspiring 360 degree panoramas of the building’s construction process.

The Design Building boasts the largest installation of wood-concrete composite floors in all of North America. Developed in part by Clouston’s lab, the composite floors are comprised of CLT panels that are connected to a 4 inch layer of concrete by means of steel mesh. The resulting floor is solid and strong and doesn’t have the vibration that is sometimes found in old mill building floors.

UMass Amherst Chancellor Subbaswamy said that it is, “Bold, beautiful and brilliant. The UMass Design Building will reflect the strength and future of this campus. The building will feature the most advanced, contemporary, engineered-wood structure in the eastern United States. Once again, UMass is leading the way in innovation.”

Let’s talk about carbon

Spoiler alert: Wood rules.

One can appreciate the UMass Design Building through a variety of perspectives: the elegance of the building itself with expansive views across campus; healthy green roofs intermingled with restive courtyards; high-tech features embedded in every aspect of design; wide open interior expanses and so much more. But from an environmental point of view, it is the life cycle assessment and carbon summary data that grabs the headlines. According to data collected by reThink Wood®, carbon savings by building with wood rather than traditional steel and concrete is staggering. For example, reference data on UMass Design Building reveals that 1463 metric tons of carbon will be stored in the wood and 1218 metric tons of greenhouse gas emissions will have been avoided through construction with wood. Carbon savings will be equivalent to 512 cars being taken off the road for a year. Enough energy will be saved to operate a home for 228 years.

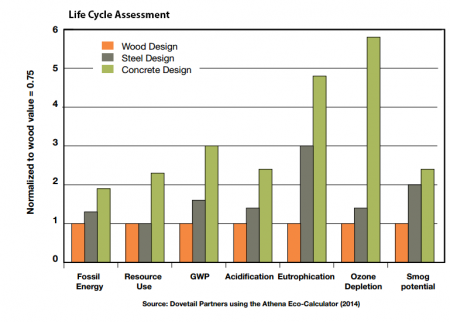

A compelling life cycle assessment (LCA) by rethink WOOD® showcases the benefits of wood construction over steel and concrete for a traditional U.S. residence. LCA is a scientific process that puts numbers to the cost of process and products over their life time. Categories such as global warming potential, fossil energy use and acidification of rivers and streams are compared. When levels of ozone depletion are stacked up against each other for wood, steel and concrete designs, it is clear that the use of concrete soars high above both wood and steel with nearly five times the level of environmental damage. The potential for smog when using concrete is twice that of wood.

A compelling life cycle assessment (LCA) by rethink WOOD® showcases the benefits of wood construction over steel and concrete for a traditional U.S. residence. LCA is a scientific process that puts numbers to the cost of process and products over their life time. Categories such as global warming potential, fossil energy use and acidification of rivers and streams are compared. When levels of ozone depletion are stacked up against each other for wood, steel and concrete designs, it is clear that the use of concrete soars high above both wood and steel with nearly five times the level of environmental damage. The potential for smog when using concrete is twice that of wood.

Consider the fact that to manufacture steel, a temperature of 1500 degrees Fahrenheit needs to be reached. This takes an enormous amount of energy and creates pollution emitting harmful noxious greenhouse gases in the process. Wood is a renewable and responsible choice that helps reduce our environmental footprint.

While some engineers and architects around the world are constructing very tall wood structures (11-30 story buildings from Vancouver to Norway), Clouston takes a more practical approach. She suggests that campuses, towns and other public entities consider constructing wood buildings in the mid-range size: four to six stories. “We don’t need to be in a competition for the tallest structures. We need to change the paradigm from building commercial buildings solely with steel and concrete to one where wood is also a material option.”

Forest Management vs. Deforestation

Inevitably, Clouston fields concerns about how incorporating much more wood in construction will affect our forests. She is quick to point out that the real threat to our forests is not the use of wood for building materials, rather it is clearing of forests for real estate development. Much of our forests in North America are vibrant. In comparison, the forests of the Amazon have been deforested for decades with wide swaths of thousands of acres cut down monthly. With much of the world’s attention on South American forests, the amount of indiscriminate clear-cutting has decreased, but it is still an issue. In contrast, when using wood for building, North American professionals use Forest Stewardship Council (FSC) certified wood that is sustainably-managed and harvested. Trees that are taken down are replanted. When managing them properly, carbon sinks are increased as young trees pull in more carbon dioxide, as opposed to older rotting trees in forests that release carbon as they decay. Clouston effortlessly offers the rationale for the use of wood in building construction. “It is more sustainable, can easily incorporate new composites and we have a lot of it. The wood used in the Design Building took 6 minutes to grow in forests in North America. Ultimately, this will also work well to manage forests. Today 70% of Massachusetts is forested and the health of these forests is in decline. Families who are land barons need markets for their trees, like CLT and Glulam, to help manage the forest economically. Often, weed and small diameter species are allowed to grow and choke out higher quality species, because of the prohibitive cost of removing them. Too many weeds and decaying trees can easily catch fire.”

Support for use of wood in mitigating climate change

Even politicians are getting excited when they understand the benefits of timber-built commercial structures. Tom Vilsack, USDA, Secretary of Agriculture, said, "By embracing the benefits of wood as a sustainable building material, these demonstration projects have the ability to help change the face of our communities, mitigate climate change and support jobs in rural America.”

In 2014, Tom Vilsack announced a $1 million program to be implemented by the U.S. Department of Agriculture (USDA) Forest Service in partnership with the Wood Products Council’s WoodWorks initiative, to provide training for architects, engineers and builders related to the use of advanced wood materials in U.S. buildings.

Jennifer Cover, PE, Executive Director of WoodWorks said, “As advanced wood products allow the use of wood in a greater variety of buildings-including high rises, we can increase the role of forests in mitigating climate change while strengthening rural economies.”

Cover shares the fact that using wood from sustainably-managed forests helps keep carbon out of the atmosphere because wood products require less fossil fuels to manufacture than other major building materials, resulting in less greenhouse gas emissions, because wood continues to store carbon absorbed from the atmosphere while the tree was still growing.

Public Education

Ever the educator, Clouston led her students in construction of a temporary public art display entitled, “Wood on the Plaza.” A massive wooden dome is sited on the plaza of the Fine Arts Center at UMass, Amherst until early July, 2016. The purpose of this dome (known in technical circles as a timber grid shell) is to demonstrate the use of wood in high-tech applications as well as to raise public awareness of recent large-scale wood construction projects, like the UMass Design Building just up the hill from the plaza, seen in the center of this photograph. Photogallery: include pdf

When completed, the Design Building will earn the coveted LEED Gold Award.

A descriptive story of how university professors, political poers and wood advocates worked in collaobration to have this building come into being can be found here.

Under the banner of UMass Amherst with interdepartmental collaborations, including the Center for Agriculture, Food and the Environment (CAFE), true building innovation is soaring to new heights, and the perspective from the top of this building overlooking the entire campus is pretty sweet.

Watch construction progress through time lapse videos here.