F-119R: Foliar Calcium Sprays for Apples

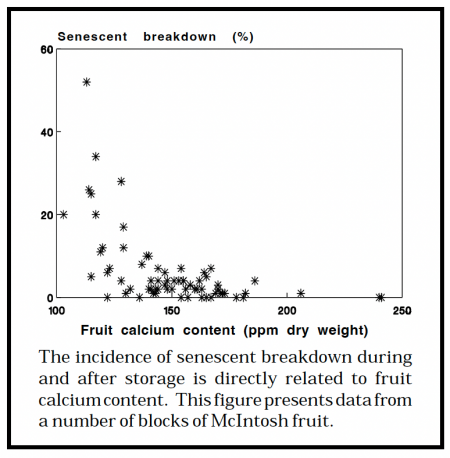

Calcium (Ca) is an important nutrient element, which can affect apple quality after harvest. Ca deficiency expresses itself in the form of cork spot, which develop primarily during the early part of the growing season, bitter pit, which develops during the latter part of the growing season, and senescent breakdown, which forms during and after storage. Ca may affect disease sensitivity during the growing season, and may affect the development of scald and decay during storage. All of these disorders result in nonmarketable fruit.

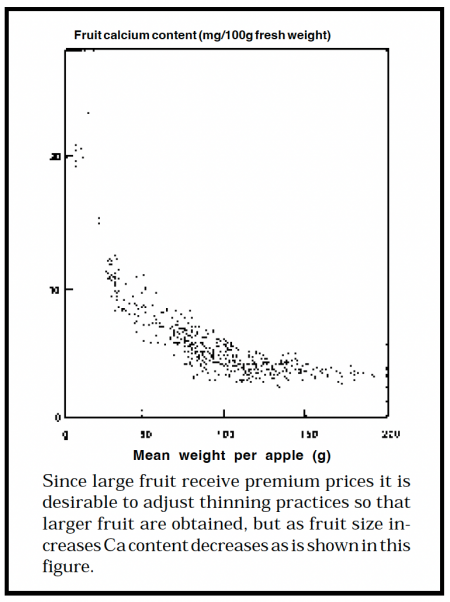

As can be seen in the graph to the left, Ca concentration is less in large fruit than in small fruit. Therefore, small fruit will store better than large fruit. Market demands and price differentials, however, force growers to thin developing fruit so that they are able to maximize the number of large apples at harvest. To provide adequate storability to these fruit, it is essential to increase their Ca content.

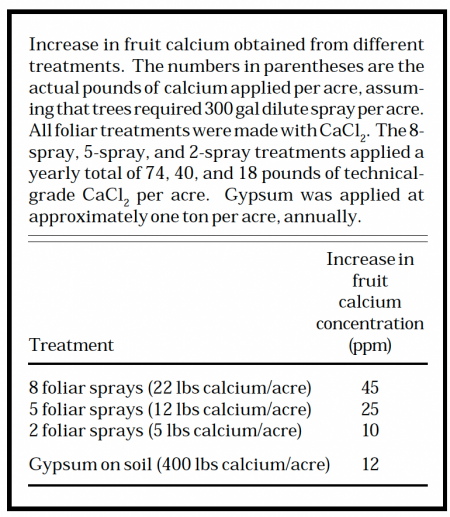

Increasing fruit Ca content can reduce the incidence of the disorders noted above. Soil, foliar, and postharvest treatments all can increase fruit Ca; however, foliar sprays are the most reliable and the most economical. The ability to control disorders is directly related to the number of spray applications made. The table below compares the effectiveness of eight, five, and two sprays and soil application with gypsum.

Materials

A number of Ca-containing chemicals are available for foliar treatment. All are equally effective if applied at the same amount of actual Ca per 100 gallons. Ca chloride (CaCl2) is the most often recommended, because it is the cheapest source of Ca. Ca nitrate {Ca(NO3)2} also may be used, but 1.6 times as much Ca(NO3)2 as CaCl2 is required to apply the same amount of Ca. The commercial material, StopitTM, also provides Ca in a foliar spray, and one pound of CaCl2 is equivalent to approximately 1.8 quarts of StopitTM. Please note that in some cases, such as with StopitTM and other commercial materials, label rates will not provide equivalent amounts of Ca as obtained from the recommended amount of CaCl2.

Treatments

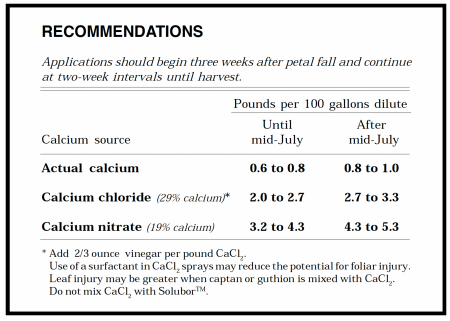

Begin foliar sprays three weeks after petal fall and continue at two-week intervals, if possible, until harvest. Eight foliar sprays ideally should be applied before the fruit are harvested. The rates and timings can be adjusted somewhat, but attempt to apply the equivalent amount of Ca per year.

Technical grade CaCl2 (~79% actual CaCl2, ~29% actual Ca) should be applied at the rate of 2.0 to 2.7 pounds per 100 gallons dilute until mid-July and at the rate of 2.7 to 3.3 pounds per 100 gallons dilute after mid-July. CaCl2 increases the pH of the spray solution, so 2/3 ounce of vinegar (5 %) should be added per pound of CaCl2. The addition of a surfactant may reduce the potential for leaf injury and increase uptake. Leaf injury may be enhanced by the addition of captan or guthion to the CaCl2 spray, but most pesticides are compatible with CaCl2. Do not, however, mix CaCl2 with SoluborTM.

Soluble, granular Ca(NO3)2 {79% actual Ca(NO3)2, 19% actual Ca} may be substituted for CaCl2 but must be applied at the rate of 3.2 to 4.3 pounds per 100 gallons dilute until mid-July and at the rate of 4.3 to 5.3 pounds per 100 gallons dilute after mid-July. Since Ca(NO3)2 does not raise the pH of the spray solution, vinegar is not required. We have tested Ca(NO3)2 only on McIntosh, and have experienced no fruit injury; however, there are reports that Ca(NO3)2 causes fruit spotting on Delicious and Golden Delicious. We have measured no increase in leaf nitrogen levels from the recommended dosage of Ca(NO3)2, and therefore expect no reduction in red coloration.

Foliar Injury

Foliar injury has been noted when CaCl2 foliar sprays have been used. Injury appears as a burn at the margins of the leaves. We feel that in most cases this injury is associated with inaccurate sprayer calibration, since the injury is not as prominent when dilute applications are used. Concentrations up to 10X have been very effective, but any inaccuracy in calibration can affect the actual application rate dramatically and result in leaf burn.

Economic Considerations

CaCl2 costs approximately $15 per acre per year. Four Ca applications may be made with other routine spray treatments for pest control, so the only application costs for CaCl2 are from four applications for Ca treatment alone. The cost of these four applications is between $40 to $60 per acre. Therefore, the total cost of Ca treatment is between $55 and $75 per acre per year. Estimates suggest that reductions in bitter pit, cork spot, decay, and senescent breakdown result in $350 to $750 higher net returns, not including the cost of application. Clearly the economic benefits of Ca application far exceed the costs. Recent trends toward larger and larger fruit greatly intensify the need for Ca treatment.

UMass Extension Factsheet F-119R

Issued by University of Massachusetts Extension, Stephen J. Demski, Director, in furtherance of the acts of May 8 and June 30, 1914. University of Massachusetts Extension offers equal opportunity in programs and employment. F-119R:6/01-500