Post-Harvest Handling & Sanitation

General Postharvest Handling & Sanitation Information

Sanitation on the farm, with the aim of preventing harvested produce from becoming contaminated, begins with general good housekeeping practices. Some general good practices to follow on your farm include:

- Training workers on personal hygiene and cleanliness (see our Worker Health, Hygiene, and Training page for more information)

- Keep it clean: sweep, pick up trash, and remove cull piles from buildings at least daily.

- Separate produce handling areas from other farm activities (tractor repair/storage, pesticide mixing, equipment storage, etc)

- Provide proper toilet and handwashing facilities and break areas for employees and farm visitors (see Worker Health, Hygiene, and Training section for more information)

- Minimize standing water. Bacteria thrive and multiply in water, so standing water, both in the field and in farm buildings, can act as a significant source of contamination. If you’re building a new pack house, design drainage systems to prevent water from pooling anywhere. If water regularly pools in existing pack houses, take measures to regularly clear that water – sweep/mop/squeegee the water out of the area regularly. If your packing area is outside, be sure that area drains well. A gravel pad can help with drainage and soil splash.

- Establish pest management programs. See “General guidelines for pest management within farm buildings” section below for specific recommendations. Overall, it is important that any pest management program be substantial and effective, or modified if they are not effective. You may need to hire a pest control company.

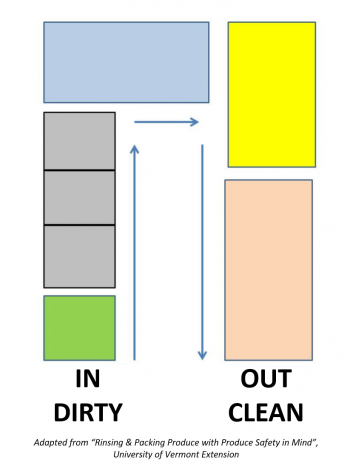

Design your wash and packhouse layout to prevent contamination. Wash and packhouse flow should move from dirty to clean, without overlapping routes. Layouts that are U- or L-shaped (see diagram) are good designs. These layouts ensure that clean, fresh produce won’t come into contact with potential contaminants coming in from other produce, truck tires, workers shoes, or other sources. Clearly label tools and equipment that is used for specific tasks so that there’s no mistaking, for example, which containers are for bringing out to the field and which are for packing clean produce.

Design your wash and packhouse layout to prevent contamination. Wash and packhouse flow should move from dirty to clean, without overlapping routes. Layouts that are U- or L-shaped (see diagram) are good designs. These layouts ensure that clean, fresh produce won’t come into contact with potential contaminants coming in from other produce, truck tires, workers shoes, or other sources. Clearly label tools and equipment that is used for specific tasks so that there’s no mistaking, for example, which containers are for bringing out to the field and which are for packing clean produce.

Infrastructure changes involving food safety can be expensive. The Massachusetts Department of Agricultural Resources has annual grant funding available through the Agricultural Food Safety Improvement Program. See their website for more information.

See "Additional Resources" at the bottom of this page for the Produce Packshed Design for Safety & Efficiency video series from the University of Vermont.

Good business practices support financial viability and farm food safety. General organization, good recordkeeping and effective communication and labor management are all essential for any business to succeed. Organization and efficiency are also key to preventing and managing produce contamination. The concept of “lean” in production deals with minimizing waste while maintaining productivity. Originating in the automobile industry, the concept can be applied to agriculture as well. Some suggestions for further reading on lean farming and farm business management that can also lead to improved farm food safety practices:

Cleaning & sanitizing:

In addition to general cleanliness, it is important to know how to clean and sanitize tools, equipment, and surfaces effectively. While cleaning and sanitizing should be focused on food contact surfaces – any surface that comes into physical contact with produce – you should also clean and sanitize “secondary” surfaces that may indirectly contact food or food contact surfaces.

Cleaning and sanitizing refer to separate actions. Cleaning refers to the physical removal of dirt and organic matter from surfaces, using water and a detergent. Sanitizing is the treatment of a cleaned surface to reduce or eliminate microorganisms. A dirty surface cannot be sanitized – cleaning always comes first.

Cleaning and sanitizing is a four-step process:

- Remove any obvious dirt or debris from the surface

- Apply detergent and scrub. Detergents should be appropriate for use on food contact surfaces.

- Rinse the surface with clean water to remove soil and detergent.

- Apply sanitizer approved for use on food contact surfaces. Rinse if required by label.

If allowed to grow on a surface, bacteria will create biofilms, which are layers of bacteria and excreted substances that allow bacterial colonies to stick onto a surface. Biofilms mostly consist of non-pathogenic bacteria, but act as sticky harbors for any passing pathogenic bacterial cell to attach to and reproduce in. If biofilms are established, it increases the likelihood that pathogenic bacteria will remain on a surface and proliferate, and so it is important to avoid the formation of biofilms on harvest, wash, and pack equipment by cleaning plant debris and soil off of equipment daily. Hard-to-clean surfaces (like wood or surfaces with bumpy seams) should be cleaned and sanitized more frequently than easy-to-clean surfaces. Routine use of sanitizers can help prevent the buildup of biofilms.

Detergents/cleaners do not need to be labeled for food contact surfaces to be used on your farm. For organic operations, detergents/cleaners do not need to be organic. Sanitizers are pesticides and must be labeled for use on food contact surfaces, and organic operations are limited to using sanitizers with specific active ingredients. See the resources below for organic sanitizer options.

- Organic Food Contact Surface Detergents and Sanitizers

- BioSafe and Ecolab both offer food industry cleaners and sanitizers. Visit their websites for more information.

- Labeled Sanitizers for Produce - Excel Tool

- Use the following resource to search for relative user/environmental safety ratings and efficacy ratings based on type of contamination, surface type, and cleaning method: Cleaner Safety and Efficacy Ratings - Toxic Use Reduction Institute

- Sanitation Schedule Template (page 7) - North Carolina State University

General guidelines for pest management within farm buildings:

- Place traps and bait stations strategically. Check traps and restock bait stations frequently.

- Inspect walls, doors, windows for holes and cracks, and fix any found.

- Deter birds with nets or spikes.

- Keep doors and windows closed as much as possible.

- Cut grass around building.

- Remove cull piles and garbage from buildings at least every day or as needed.

- Keep produce covered when possible.

- Don’t use bait inside packing areas.

- Store pallets of produce at least 1 foot from walls to aid in visual inspection and trap monitoring, or be sure they are easily moveable to aid in inspection.

- Put your pest control plans in writing and keep records of when traps are checked, baits are replaced, or other pest management activities are completed.

Resources

Bait Stations for Controlling Rats and Mice - University of Missouri Extension

Controling Birds Around Farm Buildings - PennState Extension

Rodent-Proof Construction: Drains and Pipes - University of Nebraska-Lincoln Extension

Rodent-Proof Construction: Structural - University of Nebrasca-Lincoln Extension

Chemical and Physical Contamination

Microbial contamination is not the only concern on farms. Chemical and physical contamination can also pose risks in wash and pack houses. Chemicals like pesticides, detergents, and sanitizers or physical contaminants like broken glass, wood or metal splinters, or nuts and bolts that accidentally end up in wash water or on clean produce can also pose serious threats to public health. While FSMA does not include requirements regarding chemical or physical contamination, other food safety certification programs may include such requirements, and other legislation (Worker Protection Standards, pesticide legislation, etc) includes relevant regulations.

To prevent chemical and physical contamination of produce:

- Keep cleaning and sanitizing products and pesticides in separate, clearly labeled locations.

- Keep Safety Data Sheets (SDS) for any chemical you have on the farm on site in case of an emergency. SDS can be found on chemical company websites for any cleaner, pesticide, or other chemical, and contain information about what to do if the product is ingested.

- Use only food-grade lubricants, oils, and chemicals, according to their labeled use.

- Use equipment made of food-grade materials that will not leach into produce.

- Screen or cover overhead lights or replace with shatterproof fixtures.

- Set a schedule to check bearings and metal parts of machines.

- Keep packing materials and produce covered whenever possible.

FSMA: Postharvest Handling & Sanitation

The FSMA Produce Rule does not include many explicit requirements for this section. However, the rule does include several nonprescriptive requirements without detailing how growers are supposed to meet those requirements. We have included recommendations for how to meet such requirements in this section. To distinguish explicit FSMA requirements from our recommendations, explicit FSMA requirements are written in bold font in this section. Normal text represents recommendations or additional information.

Several topics in this section refer to “covered” versus “exempt” produce. See the explanation of covered versus exempt produce on our FSMA Information page.

Tools & Equipment

Tools, Equipment, and other Food Contact Surfaces

The “tools and equipment” referred to in this section of the FSMA Produce Rule include packing and harvest containers, packing equipment, hands and clothing, buildings (coolers, storage areas), transport vehicles, and any other equipment that may come into contact with produce that is covered in the law. To comply with FSMA, you must meet the following requirements:

- Must be inspected, maintained, cleaned, and as appropriate, sanitized, as frequently as reasonably necessary to protect against contamination. This also means that all equipment must be cleanable. Avoid using materials that cannot be dried, like carpet. Wood may be used, but allow wooden equipment and surfaces to air dry after each cleaning. For surfaces that are harder to clean (like wood or surfaces with irregular seams), clean them more frequently.

Of course, it is not always economically feasible to replace existing equipment that may not be the best, most-cleanable option. When that is the case, contact your FSMA technical support provider or state produce safety team to set the best course of action. Contact information can be found on our FSMA Information page. Make sure that any new equipment you may buy is designed to be easily cleaned and sanitized. The Massachusetts Department of Agricultural Resources has annual grant funding available for food safety infrastructure through the Agricultural Food Safety Improvement Program. See their website for more information.

Another aspect of keeping harvest and postharvest equipment clean is avoidance. Avoid bringing soil into packhouses by minimizing contact between harvest containers and the soil.

The frequency of tool and equipment cleaning and sanitizing will depend on your operation. Establish cleaning/sanitizing frequency protocols and keep records of when tools/equipment are cleaned.

See the top of this page for general information about cleaners and sanitizers, including a list of products labeled for use on food contact surfaces and requirements for organic operations.

- Place equipment in locations where you can easily clean and maintain it.

- Any seams on equipment or tools must be smoothly bonded or kept clean if not. Nooks and crannies catch bacteria and make surfaces difficult to clean. If you cannot replace equipment with irregular seams, clean that equipment more frequently to avoid buildup of bacterial biofilms.

- Use single-use packing materials OR, if re-using packing materials, clean or use clean liner each time. Packing materials must be unlikely to support growth or spread of bacteria.

- Clean and sanitize, as necessary, any tools and equipment that contact exempt produce before using on covered produce. See description of covered versus exempt produce at the beginning of the FSMA and Postharvest Handling section of this page. If you use the same growing, harvesting, packing, and storing practices for both covered and exempt produce, you do not need to clean or sanitize equipment between crops unless there is an outstanding food safety issue.

- Ice and ice slurries should be stored in clean containers in a clean area. Set a schedule to clean and sanitize ice machines and storage containers and areas, and record when they are cleaned. Minimize standing water from melting ice. Ice must be made from potable water, with no detectable generic E. coli (see our Agricultural Water page for more information).

Other Tools & Equipment

- Keep non-food contact surfaces clean (sides of equipment, floor, etc) to prevent contamination of produce or food contact surfaces.

- Maintain, monitor, and routinely calibrate any relevant sensors (thermometers, pH, sanitizer efficacy, etc). You must also have enough of any relevant sensors to cover the space they are being used in. For example, if you have a large cooler, make sure you have enough thermometers to accurately measure the temperature across the entire cooler, not just right next to a blower. See the resources below for thermostat recommendations and instructions on thermometer calibration.

Thermostats for Agriculture - University of Vermont Extension

Thermometer Calibration Guide - Kansas State University

Thermometer Calibration Illustration - Kansas State University

Recordkeeping:

You must keep records of the date and method of cleaning and sanitizing equipment, tools, and containers.

![]() Equipment Cleaning and Sanitizing Log

Equipment Cleaning and Sanitizing Log

Where can I find this information within the FSMA Produce Rule?

Sections §112.121 through §112.124

Vehicles

The best-case scenario would be to have vehicles that are used solely for transporting fresh produce, but that is not always possible. It’s fine to use vehicles for multiple purposes, including transporting produce, but you must:

- Operate vehicles and pallets to prevent contamination of transported produce or any nearby produce.

- Clean vehicles before loading produce, or use a clean liner. Disposable truck bed liners are available.

Refrigerated vehicles: Inspect refrigeration units and monitor the inside temperature regularly to ensure that the units are functioning properly and that no seals are leaking.

If you hire transportation for your produce, you can stipulate in your contract that any vehicle used to transport your produce must be cleaned before your produce is loaded, and that drivers/cleaners must fill out a recordkeeping log that you provide. If you hire refrigerated transportation, you can do the same with refrigeration unit inspection and monitoring.

Recordkeeping:

If you use vehicles to transport your produce, keep records of when and how you clean the vehicles, using the log below.

![]() Equipment Cleaning and Sanitizing Log

Equipment Cleaning and Sanitizing Log

Where can I find this information in the FSMA Produce Rule?

- Vehicle operation – §112.123(e)

- Vehicle cleaning – §112.125

Pest Control

FSMA requires that any building, cooler, or storage space that fresh produce enters into must have a pest control program, in addition to the other building requirements in the following section. The level of control you have over a given building depends on how open the building is to the surrounding environment, and so requirements differ slightly for fully versus partially enclosed buildings. Specifically:

- Fully-enclosed buildings must have measures in place to exclude pests

- Partially-enclosed buildings must have measures in place to prevent the establishment of pests. For example, this could include the use of screens or spikes to prevent birds from nesting in rafters, or routinely monitoring for pests and removing any that enter the building.

You must also minimize the potential for trash to attract or harbor pests. Remove trash from buildings daily or as frequently as needed to keep out pests. Arrange for dumpsters to be emptied regularly and increase the frequency if pests are a problem nearby.

See top of page for general recommendations on keeping pests out of buildings and keeping produce safe from pests.

Recordkeeping:

Keep records of all pest control actions you take, using the logs below.

Where can I find this information in the FSMA Produce Rule?

- Pest exclusion from buildings – §112.128

- Pest exclusion from trash – §112.132(a)(1)

Buildings – Produce Washing/Packing & Cold Storage Areas

Any building in which produce is washed, packed, or stored, whether or not it is fully or partially enclosed, must:

- Be big enough for equipment and storage

- Be designed to separate operations where contamination is possible. Separation can be by:

- Location (dirty field tools are stored in one section of a building, away from produce washing and packing)

- Time (dirty field tools enter the washroom but not when there is fresh produce being washed or packed, and the room is cleaned afterward)

- Partitions

- Enclosed systems

- Have adequate drainage to avoid liquid waste/water from pooling on the ground or floor of the building. Generally, you should avoid pooling water on the floor, as microorganisms will thrive and reproduce in water and contaminated water can easily be splashed onto fresh produce. If you’re building a new structure, make sure it is designed to have adequate water drainage. With existing buildings, if you have consistently pooling water, make a plan to avoid contamination of produce from that water: route workflow away from the pooled water, consistently mop/squeegee/sweep the water out of the area and allow it to dry, especially at the end of each day, make sure workers are aware of the potential risk and know what to do if produce gets splashed by that water.

- Have measures in place to prevent contamination from:

- Dripping water and condensation, including from pipes and cooling units. Keep pipes and cooling units in good repair and ensure that they are installed correctly. Condensation pans from cooling units should empty directly into a drain or outside, and not onto the floor. If there is potential for drips or condensation to form on a surface, clean and sanitize that surface regularly to ensure that water forming on that surface will not contain harmful pathogens.

- Floors, walls, ceilings, fixtures, ducts, and pipes. Keep the listed surfaces/structures clean and in good repair. See the table below for recommendations on how frequently and with what method and material to clean various structures.

![]() Building Cleaning Recommendations

Building Cleaning Recommendations

In general, domesticated animals should be kept out of fully-enclosed buildings where produce, food contact surfaces, or food-packing material is exposed. If that is not possible, animals should be separated from such materials by location, time, or partition. Service and guard dogs are allowed in fully-enclosed buildings as long as you have systems for preventing contamination by the dog of produce, food contact surfaces, and food-packing material.

Washing/Packing Areas:

All general building requirements apply to washing and packing areas.

Keep covered produce separate from exempt produce. See above for description of covered versus exempt produce. If you use the same growing, harvesting, packing, and storing practices for both covered and exempt produce, you do not need to clean or sanitize equipment between crops unless there is an outstanding food safety issue.

Identify and then create protocols to avoid contaminating produce from the following potential sources:

- Surfaces that produce touches directly (food contact surfaces)

- Surfaces that employees may touch before/after touching produce

- Objects or areas within the wash/pack house that could pose potential contamination risks to produce (including cull piles, trash cans, foot traffic areas, storage areas)

- Objects or areas outside of the wash/pack house that may pose potential contamination risks to produce (including compost piles, truck routes, domesticated animals)

Map the flow of produce from the field through your pack area. The area should have a clear flow from dirty to clean produce, with minimal overlapping routes, to minimize contact of potential contamination from the field with clean produce. See the diagram at the top of this page for an example of a "U"-shaped wash/packroom setup.

Cold Storage Areas:

All general building requirements apply to cold storage areas.

Cooling of produce is not required by FSMA, but if you do store your produce in a cool room, you must do it in a way that doesn’t pose contamination risks. Specifically, you must:

- Take measures to avoid contamination from dripping water or condensation. This is especially important in cold storage areas, as the human pathogen Listeria monocytogenes can survive and reproduce at refrigeration temperatures, whereas other pathogenic bacteria cannot. Regularly clean and sanitize any surfaces within coolers – ceiling, walls, shelving, etc. – including in refrigerated vehicles. Keep produce in coolers covered as much as possible. Avoid standing water in coolers. Condensation pans from any cooling units should slope directly into a drain or outside, not onto the floor.

- Have an adequate number of any necessary sensors or controls (thermometers, thermostats, coolbots, humidity sensors) to cover the area in use. For example, for a large cooler, you need to have enough thermometers to accurately monitor any temperature differences across the entire cooler.

- Any sensors or controls in use must be accurate and precise and adequately maintained.

Thermostats for Agriculture - University of Vermont Extension

Within any cold storage areas, you should also:

- Establish a pest control and cleaning program.

- Inspect cooling units regularly to make sure they are functioning properly.

- Make sure that coolers are holding their temperature by inspecting door and window seals regularly, and monitoring and recording cooler temperatures at the beginning of each day.

Where can I find this information in the FSMA Produce Rule?

- General building requirements: §112.121

- Keeping covered and not-covered produce separate §112.111

- Instruments and controls used to measure, regulate, or record: §112.124

Recordkeeping, SOPs, and Worker Training

The only recordkeeping required for all farms by the FSMA Produce Rule regarding postharvest handling and sanitation is the date and method of cleaning and sanitizing equipment, tools, and containers. See template below.

However, the basic rule for FSMA recordkeeping is: if you do it, keep a record! FSMA requires growers to “avoid contamination” from many sources in this section, but does not prescribe specific ways to do so. To show that you are taking measures to avoid produce contamination, you should develop standard operating procedures (SOPs) for and keep records of any cleaning and sanitizing activities to show that you are monitoring your buildings, tools, and equipment for food safety risks and cleaning and sanitizing them according to appropriately set schedules. Below are some suggested templates to use for some common tasks. Feel free to adapt them to your own operations.

Equipment Cleaning and Sanitizing Log (required) – use for equipment, tools, packing surfaces, vehicles, etc.

Equipment Cleaning and Sanitizing Log (required) – use for equipment, tools, packing surfaces, vehicles, etc. Pest Control Log

Pest Control Log Bait Station Log

Bait Station Log Building Inspection Log - Daily

Building Inspection Log - Daily Building Inspection Log - Monthly

Building Inspection Log - Monthly Building Inspection Log - Quarterly

Building Inspection Log - Quarterly Monitoring Tool Calibration Log

Monitoring Tool Calibration Log

FSMA requires that all workers be trained so that they know how to identify and reduce risks. Workers should be trained on sanitation SOPs and should know what to do if they observe a risk to covered produce. When recording worker trainings, as required by the rule, include sanitation topics in the list of topics covered (see our Worker Health, Hygiene, and Training page for more information.)

Where can I find this information in the FSMA Produce Rule?